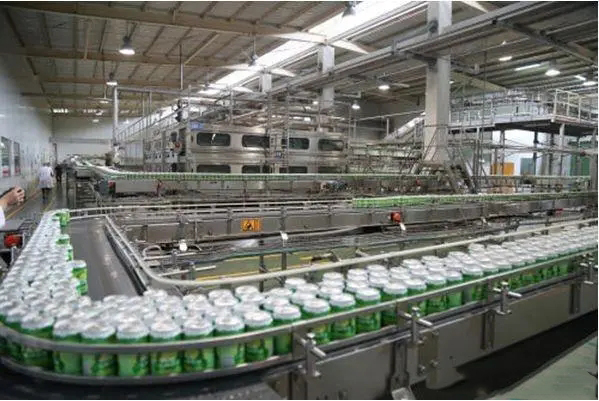

Application of Pneumatic Technology in Food and Beverage Industry

Application of Pneumatic Technology in Food and Beverage Industry

Pneumatic Technology Is An Effective Means Of Automating And Mechanizing The Production Process.

It Has The Advantages Of High Speed, High Efficiency, Safety, Low Cost, And Easy Maintenance.

It Is Widely Used In The Field Of Light Industrial Machinery And Is Playing An Increasingly Important Role In Food Packaging And Production Processes.

It Can Reduce The Auxiliary Processing Time, Decrease The Labor Intensity Of Workers, And Maximize The High-Efficiency Performance Of The Equipment.

The Problems Of "Bacteria" And "Foreign Matter Mixing" In Food Have Gradually Attracted Widespread Attention From All Walks Of Life.

Therefore, It Is Necessary To Carry Out Safety Inspections On Products Frequently, And The Equipment Should Be Cleaned At Least Once a Day.

Therefore, The Design Of Pneumatic Components Is Different From That Of General Products Regarding Material, Shape, Structure And Lubricant.

It Can Be Used Under Harsh Conditions Of Strong Splash, High Temperature, Low Temperature, High Speed And High Frequency To Make sure The Production Of Safe And High-Quality Food.

Typical Food Preparation Process From Raw Materials-Processing (Flavoring)-Blowing/Filling - Packaging - Product Inspection - Bundling, Leaving The Factory

During The Production Process, Raw Materials Are Fed In Using a Solenoid Valve That Controls The Amount Of Food.

Some High-Pressure Pneumatic Components Are Required To Make Pet Bottles, Which Are Containers For Filling Beverages.

In The Packaging Process, Static Eliminators Are Used To Eliminate Static Electricity To Prevent Errors During Labeling.

During Product Inspection, If Defective Products Are Found, It Is Necessary To Use Fast-Response Valves To Control The Appropriate Air Claws And Cylinders To Drop The Defective Products And Quickly Push Them Off The Transmission Belt.

Various Types Of Vacuum Suction Cups And Various Types Of Cylinders Are Required For Baling And Packaging Operations.

In Food Machinery, Stainless Steel Pneumatic Cylinders With Strong Water Resistance And Sanitary Cylinders Are Often Used, Which Can Increase The Water Resistance By About 5 Times Compared With Ordinary Waterproof Cylinders.

Pneumatic Color Selection Machines For Quality Identification Of Rice, Tea, Beans And Other Foods Need To Use High-Frequency Valves To Blow Off Defective Products At An Extremely Fast Speed. In Addition, There Is Also a Pneumatic Peeling Machine For Peeling Vegetables Such As Green Onions And Shallots.

(Pneumatic Execute Components&Pneumatic Control Components

&Pneumatic Parts&Accessiories&Air Source Treatment Components)

RIH Brand Strength For Pneumatic Technology

Yueqing Right Pneumatic Co., Ltd.Is A Manufacturer Of Pneumatic Products With Well-Equipped Testing Facilities And Strong Technical Force.

With A Wide Range, Good Quality, Reasonable Prices And Stylish Designs, Our Products Are Extensively Used In Automation Equipment, Machine, Building And Other Industries.

Our Pneumatic Products Are Widely Recognized And Trusted By Users And Can Meet Continuously Changing Economic And Social Needs.

We Welcome New And Old Customers From All Walks Of Life To Contact Us For Future Business Relationships And Mutual Success!

(Pneumatic Execute Components&Pneumatic Control Components

&Pneumatic Parts&Accessiories&Air Source Treatment Components)

RIH Brand Pneumatic Component Application Field Show

RIH,Be Founded In 2003.

We Have Many Years Experience With Excellent Technology Team And Professional Customer Service.

Meanwhile, Our Company Staffs A Team Of Experts Devoted To Developing Products.

Our Pneumatic Products Are Widely Applied In Industries, Such As Textile, Chemical, Mineral, Electric Power, Packing Machinery And Papermaking Industries.

Our Company Promises All Users Of The First-Class Products And The Satisfying Post-Sale Service.

We Warmly Welcome Our Regular And New Customers To Join Us For A Better Future.