Automobile Manufacturing Industry-Pneumatic Components

The situation in the auto industry is changing rapidly.

Electric mobility is part of the future, and the number of electric vehicles and commercial vehicles will continue to grow.

Established processes, structures, valves and supply chains are changing.

New drive and vehicle technologies are increasingly demanding production technologies that are not only flexible, but also intelligent and energy-efficient.

Quickly set up flexible production lines and leverage our extensive engineering and industry expertise to make sure your production performance is reliable and future-proof.

We look forward to delivering the perfect solution for the complete powertrain to move your project forward.

(Pneumatic Execute Components&Pneumatic Control Components

&Pneumatic Parts&Accessiories&Air Source Treatment Components)

(Pneumatic Execute Components&Pneumatic Control Components

&Pneumatic Parts&Accessiories&Air Source Treatment Components)

Project Introduction

The automotive industry is far ahead of other industries regarding transitioning to the Industrial Internet of Things.

Complex value chains, just-in-time production and networked manufacturing require intelligent components, suitable handling technology and flexible integrated solutions of pneumatics, electrics or hybrids.

Moreover, RIH Pneumatic must make sure energy saving and safety at the same time.

The production lines of modern automobile manufacturing plants, especially the welding lines of the main processes, almost exclusively use pneumatic technology.

For example:using automatic punching machine, punching the steel plate cut to size into various plate parts such as roof, chassis, door, engine compartment cover, cylinders) use pneumatic components to send them to the specified station for positioning and clamping.

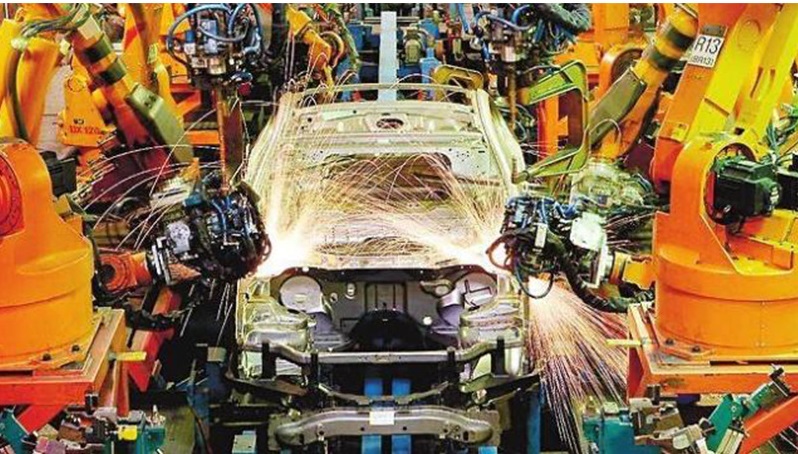

The robot makes the welding head of the spot welding machine approach quickly and decelerates after a soft landing.

Perform variable pressure controlled spot welding.

This requires using anti-spatter, anti-magnetic field, anti-vibration, large clamping force and other special requirements of the cylinder and the corresponding control system.

After the assembled body is fully cleaned, primer spraying, middle paint spraying, topcoat spraying and 3-4 times of baking paint work are carried out.

This process needs to be carried out in a dust-free paint baking room.

The pneumatic system used for spray painting needs to use a spray valve that adapts to the color changes of various paints, and is suitable for oil-free, pollution-free, explosion-proof and solvent-resistant environments.

It also needs remote control and proportional control of various batteries, flow switches, soft pneumatic components such as pipes.

Pneumatic technology is widely used in the processing, transportation and automatic assembly of power components such as engines and gearboxes and other components.

A serial transmission system is required to read the signals from each sensor and serially control multiple solenoid valves to increase the level of automation.

Cooling treatment during processing requires using coolant valves and cylinders with strong water resistance.

For environmental protection and energy saving, industrial filters that do not need to replace filter elements can be used, energy-saving nozzles can be used, and pressure switches,flow switches,etc. can be used for reasonable pressure.management and traffic management.

(Pneumatic Execute Components&Pneumatic Control Components

&Pneumatic Parts&Accessiories&Air Source Treatment Components)

(Pneumatic Execute Components&Pneumatic Control Components

&Pneumatic Parts&Accessiories&Air Source Treatment Components)

RIH Brand Strength For Pneumatic Components

Yueqing Right Pneumatic Co., Ltd.Is A Manufacturer Of Pneumatic Products (Pneumatic Execute Components&Pneumatic Control Components&Pneumatic Parts&Accessiories&Air Source Treatment Components) With Well-Equipped Testing Facilities And Strong Technical Force.

With A Wide Range, Good Quality, Reasonable Prices And Stylish Designs, Our Products Are Extensively Used In Automation Equipment, Machine, Building And Other Industries.

Our Mini Pneumatic Cylinder Are Widely Recognized And Trusted By Users And Can Meet Continuously Changing Economic And Social Needs.

We Welcome New And Old Customers From All Walks Of Life To Contact Us For Future Business Relationships And Mutual Success!