Food Packaging Industry-Pneumatic Components

Food Packaging Machinery Must Meet The Relevant Requirements And Regulations Of Food Machinery Safety, And The Work Site Environment Is Generally More Complex And Harsh, If Inappropriate Pneumatic Components Are Used, Abnormal Phenomena Will Often Occur.

Modern Food Packaging Machinery Usually Integrates Mechanical, Electrical, Hydraulic And Pneumatic Technologies, And There Is An Inseparable Connection Between Each Part.

The Failure Of Any Part Will Affect The Normal Operation Of The Equipment.

Therefore, In The Design And Application Of The Pneumatic Part Of Food Packaging Machinery, It Is Necessary To Choose Reliable Products That Meet The Actual Needs.

In Food Production, The Hygiene Requirements Of Different Production Areas Are Different

The European EN1672-2 Standard Defines The Environment Of Food Processing Machinery As 3 Working Areas, Namely Food Area, Splash Area And Non-Food Area.

According To The Hygienic Requirements Of Different Regions, The Pneumatic Technology And Products Required Are Also Different.

Food And Splash Zones Require Safety And Hygiene

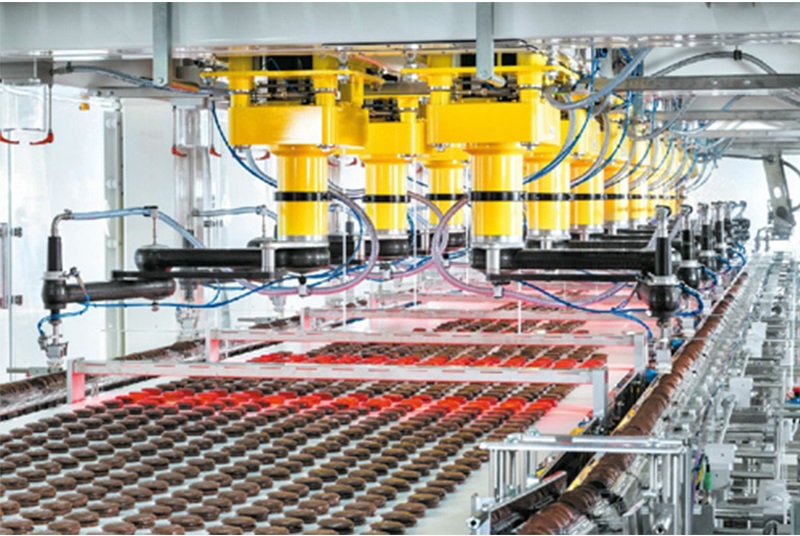

In The Food Zone And Splash Zone, Pneumatic Technology Is Mainly Used In Devices Such As Dispensing, Bottling, Forming, Filling, Dispensing And Sealing.

Since Pneumatic Components Need To Be In Direct Or Indirect Contact With The Main Production Raw Materials, To Avoid Contamination Of The Final Product, Its Material Should Be Non-Toxic, Non-Absorbent And Corrosion-Resistant Stainless Steel Originals.

If Aluminum Alloy Material Is Used, It Should Have Certain Corrosion Resistance, No Toxicity And No Absorption.

The Rubber Products Used Inside The Components, Such As Seals, Should Meet The Corresponding Hygienic Requirements, And Should Have The Characteristics Of Heat Resistance, Acid And Alkali Resistance, And Oil Resistance, And Can Be Cleaned And Disinfected Normally. Affects The Odor Of The Product.

The Working Air Filter Device Should Ensure That Dust Above 5μm Is Prohibited From Passing Through.

The Structure And Surface Should Be Smooth, Durable, Easy To Clean And Can Achieve Good Cleaning Effect.

Although The Design Of The Splash Area Needs To Be Similar To That Of The Food Area, The Material Requirements Can Be Reduced As Appropriate, And The Design Must Not Adversely Affect The Food Product.

(Pneumatic Execute Components&Pneumatic Control Components

&Pneumatic Parts&Accessiories&Air Source Treatment Components)

(Pneumatic Execute Components&Pneumatic Control Components

&Pneumatic Parts&Accessiories&Air Source Treatment Components)

Increasingly Stringent Dimensional Requirements For Components In Non-food Areas

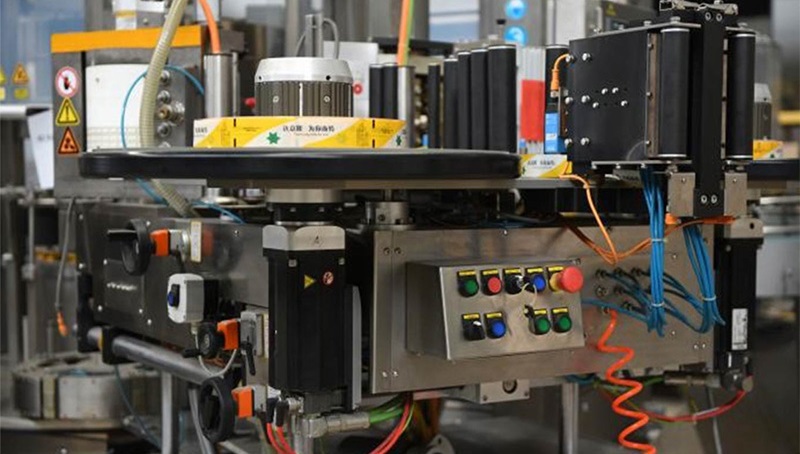

In The Non-Food Area, Pneumatic Technology Is Mainly Used In Devices Such As Bag Sealing, Packaging, Labeling, Inspection And Capping.

Although The Pneumatic Components In This Area Do Not Need To Contact Production Raw Materials, They Usually Still Need To Be Standardized, Easy To Clean, Intelligent And Environmentally Friendly. And Compact Structure.

As Today's Food Packaging Equipment Requires More Functions In a Limited Space, The Size Requirements For Pneumatic Components Are Becoming More And More Stringent.

Typical Products Include The British Norgren Easy-To-Clean Valve Island Vm Series, whose Valve Body With a Width Of Only 10mm Can Provide a Flow Rate Of 430l/Min, Can Be Integrated With 2 To 20 Positions, And Conform To Ip65 And The Trend Of Complex Control In Food Packaging.

In Addition, Advanced Food Packaging Equipment Generally Adopts a Non-Oil-Lubricated Pneumatic System Composed Of Filters, Pressure Reducing Valves, Valves And Cylinders That Are Not Lubricated By Oil, Etc.

This System Is Pre-Sealed With Grease Where The Components Need To Be Lubricated, And No Oil Is Required. Mist, Can Work For a Long Time Without Adding Grease, Can Reduce Fuel Consumption And Cost, Improve The Environment, Easy Maintenance And Stable Performance.

Intelligent Pneumatic Device

With The Increasing Improvement Of Food Processing Technology, The Automation Level Of Food Packaging Is Also Constantly Improving.

Presently, The Research And Development Of Food Packaging Machinery Is Developing In The Direction Of High Speed, Multi-Function And Intelligent Control. Industrial Robots, Microelectronics, Computers, Intelligent And Image Sensing Technology Will Be More And More Widely Used, And The Intelligence And Networking Of Pneumatic Technology Used In Food Packaging Machinery Will Also Become Inevitable.

Pneumatic Technology Is Also Widely Used In Many Industries Such As Fertilizer, Chemical Industry, Grain, Food, Medicine, Etc.,To Realize Automatic Measurement And Packaging Of Powder, Granular And Block Materials. Used In Many Processes Such As Automatic Cigarettes And Automatic Packaging In The Tobacco Industry.

Automatic Metering And Filling Of Viscous Liquids (Such As Paint, Ink, Cosmetics, Tooth Green, Etc.) And Toxic Gasses (Such As Gas, Etc.).As Can Be Seen From The Above Examples, Pneumatic Technology Has Been Widely Used In All Walks Of Life.

(Pneumatic Execute Components&Pneumatic Control Components

&Pneumatic Parts&Accessiories&Air Source Treatment Components)

Project Introduction

After Nearly 20 Years Of Development, Food Packaging Machinery Has Formed a Certain Scale And Has Become An Important Part Of The Machinery Industry.

Currently, Most Of The Packaging Work In Domestic Food Processing, Especially The More Complex Packaging Process, Is Basically Operated Manually, Which Is Likely To Cause Pollution To The Packaged Products.

This Situation Needs To Be Changed.

Currently, The State Has Stepped Up Efforts To Implement The Food Quality And Safety Market Access System, And Food Packaging Equipment Is Gradually Being Incorporated Into The Food Quality And Safety Access System, Which Is a Good Opportunity For The Food Packaging Machinery Industry To Achieve Industrial Upgrading.

Modern Food Packaging Machinery Is a Collection Of Advanced Technologies From Various Disciplines.

It Has The Characteristics Of High Efficiency, High Precision, High Automation And High Flexibility, And Is Developing In The Direction Of Intelligence And Integration.

One Of The Basic Components Is Pneumatic Technology.

Pneumatic Technology Is One Of The Effective Means Of Automation And Mechanization Of The Production Process

It Has The Advantages Of High Speed, High Efficiency, Clean And Safe, Low Cost And Easy Maintenance.

It Is Widely Used In The Field Of Light Industrial Machinery, And Is Also Playing a More And More Increasingly Important Role.

It Has Many Applications In Various Packaging Machinery, Which Can Shorten The Auxiliary Processing Time, Reduce The Labor Intensity Of Workers, And Give Full Play To The High-Efficiency Performance Of The Equipment.

(Pneumatic Execute Components&Pneumatic Control Components

&Pneumatic Parts&Accessiories&Air Source Treatment Components)

(Pneumatic Execute Components&Pneumatic Control Components

&Pneumatic Parts&Accessiories&Air Source Treatment Components)

(Pneumatic Execute Components&Pneumatic Control Components

&Pneumatic Parts&Accessiories&Air Source Treatment Components)

RIH Brand Strength For Pneumatic Components

Yueqing Right Pneumatic Co., Ltd.Is A Manufacturer Of Pneumatic Products (Pneumatic Execute Components&Pneumatic Control Components&Pneumatic Parts&Accessiories&Air Source Treatment Components) With Well-Equipped Testing Facilities And Strong Technical Force.

With A Wide Range, Good Quality, Reasonable Prices And Stylish Designs, Our Products Are Extensively Used In Automation Equipment, Machine, Building And Other Industries.

Our Pneumatic Components Are Widely Recognized And Trusted By Users And Can Meet Continuously Changing Economic And Social Needs.

We Welcome New And Old Customers From All Walks Of Life To Contact Us For Future Business Relationships And Mutual Success!