Mini Pneumatic Cylinder Model Specification Selection

What is Miniature Air Cylinders?

Applications in Industries

1. Textile Industry:

Miniature pneumatic cylinders play a crucial role in textile machinery, where precise control is essential for weaving and knitting processes.

2. Chemical Industry:

In chemical processing, these cylinders contribute to accurate dosing and positioning in various stages of production.

3. Mineral Industry:

Mining equipment often integrates miniature pneumatic cylinders for precise movements in challenging environments.

4. Electric Power Industry:

Power generation facilities leverage these cylinders for tasks requiring precision and reliability in control systems.

5. Papermaking Industry:

In paper mills, these cylinders aid in precise cutting and positioning, enhancing the overall efficiency of the papermaking process.

How much can a pneumatic piston lift?

The lifting ability of a pneumatic piston hinges on factors like piston diameter, air pressure, and system efficiency. The formula to calculate this capacity includes variables such as pressure (in PSI) and the piston's cross-sectional area (derived from its diameter). The amount of weight a pneumatic piston (or cylinder) can lift depends on several factors, including the piston's diameter, the air pressure supplied to it, and the efficiency of the system. The lifting capacity can be calculated using the formula:

Where:

Force is the lifting capacity of the piston.

Pressure is the air pressure supplied to the piston (typically measured in pounds per square inch or PSI).

Area is the cross-sectional area of the piston (calculated from its diameter).

What size are pneumatic pistons?

Pneumatic pistons, or pneumatic cylinders, are available in a wide range of sizes to suit various applications, both in industrial and commercial settings. The size of a pneumatic cylinder is primarily characterized by two dimensions: the bore diameter and the stroke length.

Bore Diameter: This refers to the diameter of the cylinder's piston. The bore size is a key determinant of the force output of the cylinder. Common bore diameters can range from small sizes like 10 mm (about 0.4 inches) to much larger sizes, often exceeding 200 mm (about 8 inches) for heavy industrial applications.

Stroke Length: This is the distance the piston can travel inside the cylinder. Stroke lengths vary significantly based on the application, ranging from a few millimeters to several meters in some industrial cylinders.

What is Miniature Threaded-Body Air Cylinders?

Miniature threaded-body air cylinders are a type of pneumatic actuator designed for applications where space is at a premium and minimal force is required. These cylinders are characterized by their small size and the threaded exterior of their bodies, which allows for easy mounting in tight spaces. These are a niche within miniature pneumatic cylinders, designed for tight-space applications. Their threaded bodies facilitate easy mounting, and they are particularly suited where minimal force and space-saving are crucial.

What is Subminiature Round Body Air Cylinders?

Subminiature Round Body Air Cylinders, often referred to in the industry as pneumatic cylinders, are compact and lightweight actuators used in a variety of automation and mechanical applications. They use compressed air to create linear motion and force in a limited space, which makes them ideal for small-scale, precision tasks.

In conclusion, whether it's a miniature pneumatic cylinder, miniature pneumatic piston, miniature air cylinders, or a mini air cylinder, each plays a vital role in various industries, offering precision, efficiency, and reliability in a compact package. This adaptability and functionality make them indispensable in modern industrial applications.

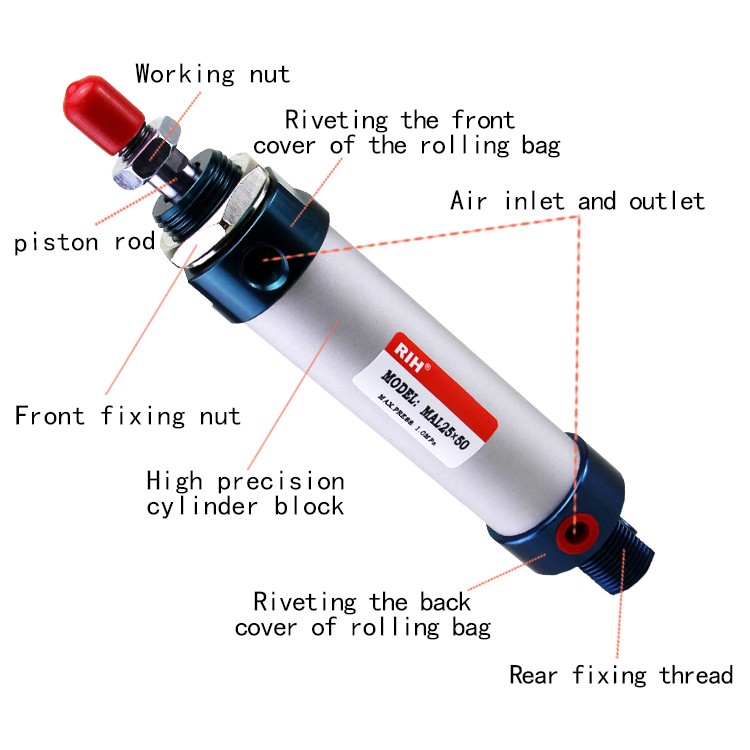

The commonly used mini cylinders are MAL aluminum alloy mini cylinders

MA stainless steel mini cylinders

DSNU mini cylinders, CM2 mini cylinders, CJ1, CJP, CJ2 and other mini cylinders.

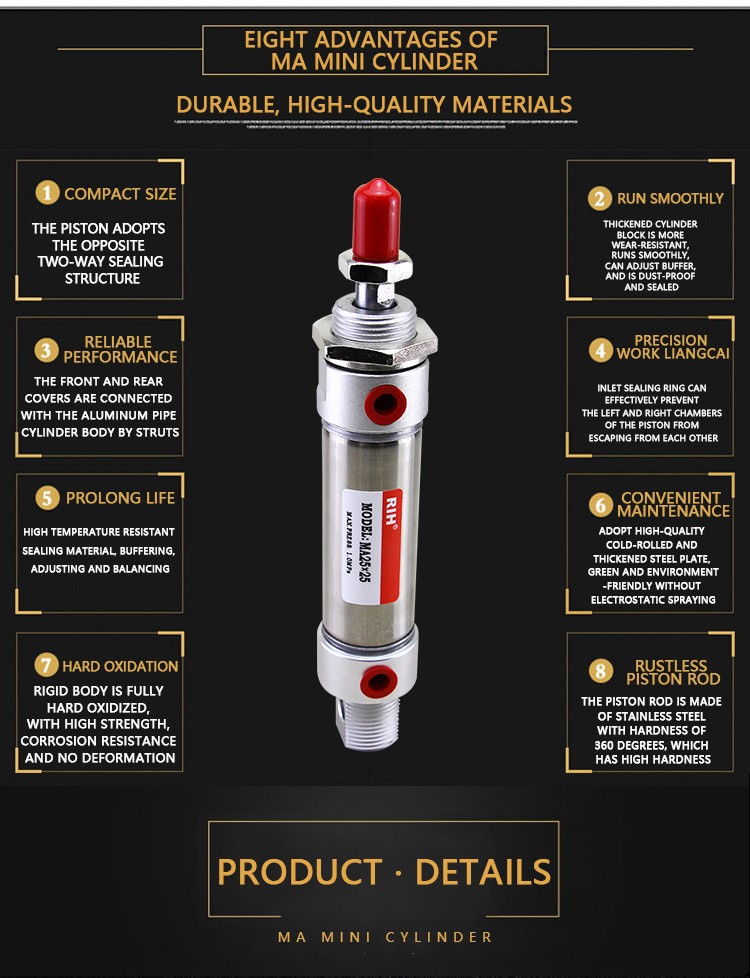

The main features and advantages of the mini cylinder,

1, mini cylinder diameter is generally divided into 6.10.12.16.20.25.32.40mm.

2, compact structure, fixed before and after thread installation, can effectively save space according to the installation, can be applied to using high frequency requirements

3, a variety of cylinder installation accessories for choice, flexible.

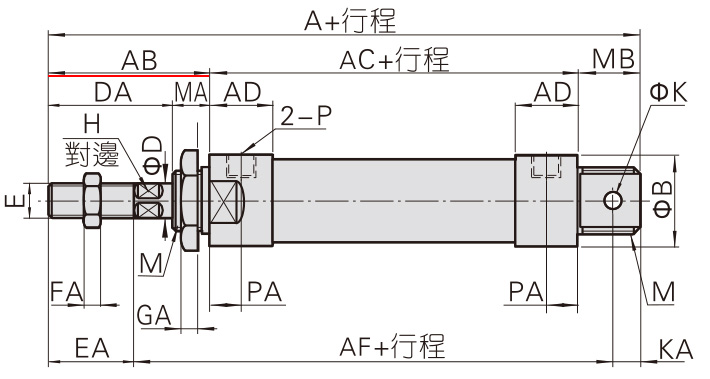

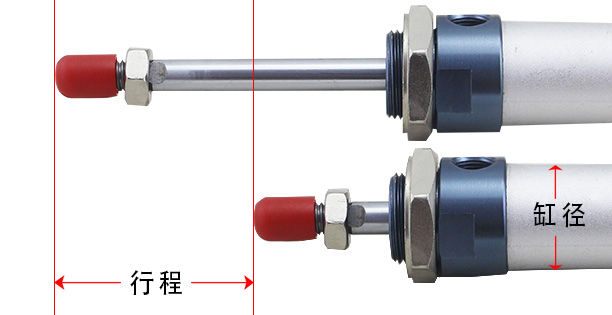

How to select the standard cylinder? Confirm cylinder diameter and stroke first

The stroke is the error distance between the piston rod extended and retracted. Some people will calculate the stroke by exposing the cylinder itself, which is wrong. Cylinder diameter is the diameter of the inner wall of the cylinder. the general outer diameter can also be estimated the size of the inner diameter, under the same pressure, the greater the cylinder diameter output.

The function of the mini cylinder commonly used in China is the same. The main difference is the appearance of the installation size and model;

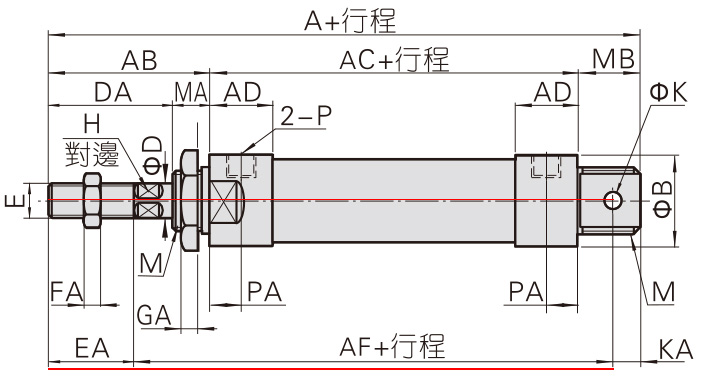

This is the basic outline of a mini cylinder, after installation: the standard tail CA installation can be replaced by confirming the size of the K mounting hole and center point to the top of the cylinder piston.

It is ok to confirm the distance of AB and the size of thread in front installation. As long as there is enough space for rear installation, it does not matter whether the tail is flat or CA.

RIH Brand Strength For Mini Pneumatic Cylinder

At Yueqing Right Pneumatic Co., Ltd. (RIH), we take pride in introducing our stellar range of Miniature Pneumatic Cylinders, setting new benchmarks in compact actuation technology. Crafted with precision and innovation, our miniature air cylinders seamlessly blend efficiency with a space-saving design, catering to the dynamic needs of modern industries.

Yueqing Right Pneumatic Co., Ltd.Is A Manufacturer Of Pneumatic Products (Pneumatic Execute Components&Pneumatic Control Components&Pneumatic Parts&Accessiories&Air Source Treatment Components) With Well-Equipped Testing Facilities And Strong Technical Force.

With A Wide Range, Good Quality, Reasonable Prices And Stylish Designs, Our Products Are Extensively Used In Automation Equipment, Machine, Building And Other Industries.

1. Space-Efficient Design:

Our miniature cylinders embody a compact design, making them ideal for applications where space is a premium.

The streamlined construction ensures easy integration into machinery without compromising on performance.

2. Precision in Performance:

RIH Miniature Air Cylinders deliver unparalleled precision in linear motion, catering to tasks that demand exacting control and accuracy.

These cylinders are engineered to provide consistent and reliable performance in diverse industrial settings.

3. Diverse Applications:

Versatility is at the core of our miniature pneumatic cylinders, finding applications across a spectrum of industries such as textiles, chemicals, minerals, electric power, and papermaking.

Adaptability to various industrial processes underscores the reliability and efficiency of RIH cylinders.

4. Energy-Efficient Operation:

Harnessing the power of compressed air, our miniature cylinders excel in converting energy efficiently, contributing to cost-effective and environmentally friendly operations.

The pneumatic technology ensures a smooth and energy-conscious performance, aligning with the sustainability goals of modern industries.

Our Mini Pneumatic Cylinder Are Widely Recognized And Trusted By Users And Can Meet Continuously Changing Economic And Social Needs.

We Welcome New And Old Customers From All Walks Of Life To Contact Us For Future Business Relationships And Mutual Success!